- Durchsuche Kategorien

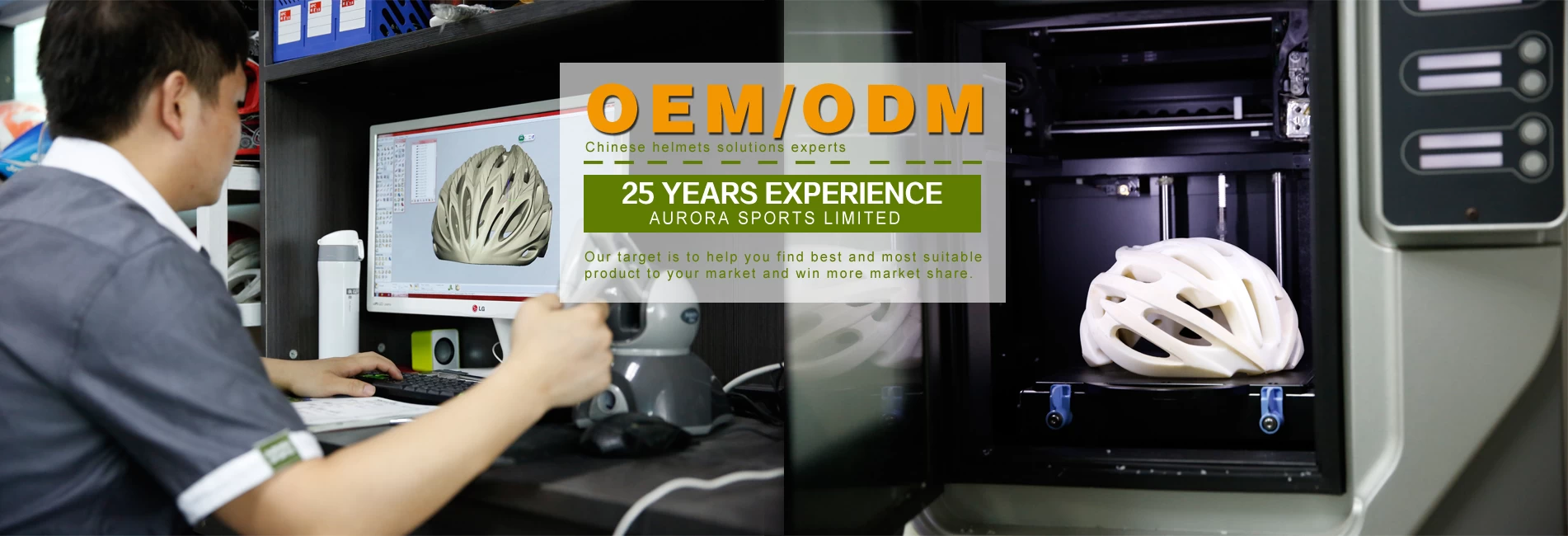

- F & E-Dienst

- Neue Designs

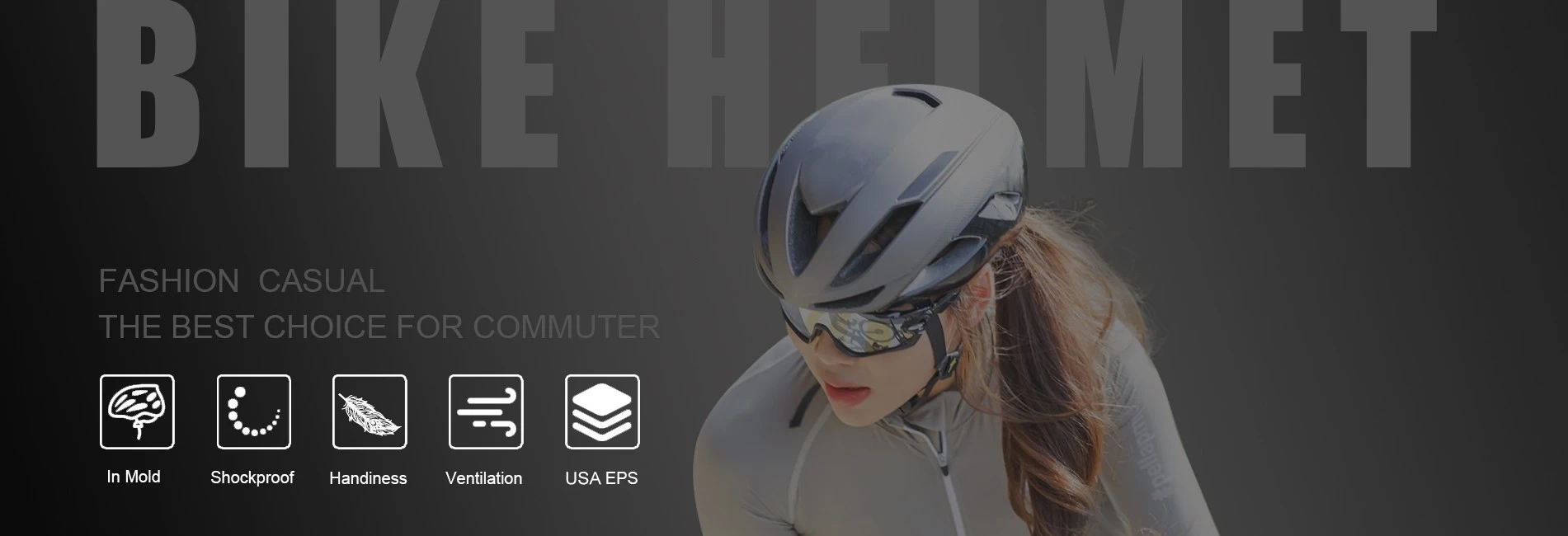

- Erwachsenen Fahrradhelm

- Kinderhelm

- Skatehelm

- Klettern Helm

- Reithelm

- Skihelm

- Schutzhelm

- Ice Skating Helm

- Eishockey-Helm

- Carbon-Teile

- Smart Helm

- Watersport Helm.

- Helmzubehör

- Zertifizierungen

-

- Neueste Nachrichten

-

Klassifizierung und Zertifizierung von Skihelme

Skihelme aus dem Geltungsbereich des Schutzes zu differenzieren: CLASS A und CLASS B. Europäischen standard CE EN1077 unterteilt in Skihelme CLASS A ...Drei Materialien für die Außenschale der Helme

Als Schutzausrüstung helmet schützt den Kopf des Trägers bei ein Unfall. Es kann reduce Verletzungen, sogar Leben retten in einigen extremen Fälle...New Helm Regel ist unwissenschaftlich

Mysuru: Mitglieder der Association of Concerned und informierte Bürger, Mysuru und anderen gleichgesinnten Organisationen ein Treffen am Institut fü...Sind Sie ein Echt Kletterer?

Sind Sie ein Echt Kletterer? Hallo alle zusammen, guten Tag! Heute wollen's über die wirklichen Kletterer sprechen. In diesen Tagen, die sich selbst ...EU Declaration of Conformity

Declaration of Conformity-Module.pdfGute Nachrichten aus dem Helm Porzellanfabrik - unsere preisgekrönte

Dies ist eine sehr glückliche Sache. vor 60 Tagen Helm-Fabrik in China ein Website-Wettbewerb teilgenommen, heute ist der Tag des Endes des Spiels. F...

- Kontaktiere uns

- Aurora Sports Limited. Büro & Show-Zimmer: # 1501-1503, Heulengshiji Gebäude, Wuhe Avenue, Bantianische Stadt, Distrikt Longgang,... Kontaktieren Sie mich jetzt

- Abonnieren

-

Erhalten Sie E-Mail-Updates zu neuen Produkten

PC+EPS in mold technique kids helmet AU-C11 light weight bike helmet for baby girl

- Aurora - Your China Helmet Expert

- Model No.: AU-C10

- Vents:16 vents

- Weight: 170g

- Material: PC+EPS in mold technique, With headkey adjustment, nylon chin strap and ITW buckle.

- Size: S/M:(46-50CM)

Cool kids bike helmets, light weight kids helmet online AU-C10

| Model No. | AU-C10 |

| Material | In-mold EPS liner & PC shell |

| Certification | CE EN1078 |

| Vents | 16 air vents |

| Color | Pantone, customized |

| size/head circumference | S/M:(46-50CM) |

| Weight | 170g |

| Sample Time | 7 days |

| MOQ | 2500pcs |

| Package details | PP bag+individual color box packing+mastercarton |

1. it's super lightest, only 160g, and well-ventilated,

2. Thicken PC shell ,protection would be sharply increased.

3. High density gray EPS material, light weight, Shock resistance,provide reliable protection .

4. with patent adjustment headlock buckle , PA webbing, washable pads.

5. Lining Pad equipped with hot-pressing technology.

6. Certification: CE-EN1078 certified for impact protection.

Package Measurements: 73X58X35 cm

Gross Weight: 6.50 kg

Package Type: 1PCS/PP bag wth color box, 12 PCS PER BROWN CARTON

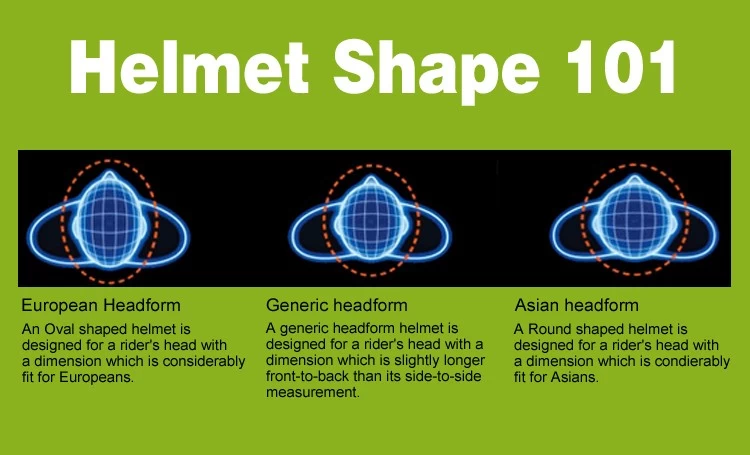

European Headform:

An Oval shaped helmet is designed for a rider's head with a dimension which is considerably fit for Europeans.

Generic headform:

A generic headform helmet is designed for a rider's head with a dimension which is slightly longer front-to-back than its side-to-side measurement.

Asian headform:

A Round shaped helmet is designed for a rider's head with a dimension which is condierably fit for Asians.

Manufacturer

Aurora Sports is a helmet manufacturer, with more than 15 years experience in producing all types of helmets. In-house design and R&D teams with established experience, allows Aurora Sports to quickly answer to demanding requirements and create from scratch whole programs and collections with rigorous quality standards.

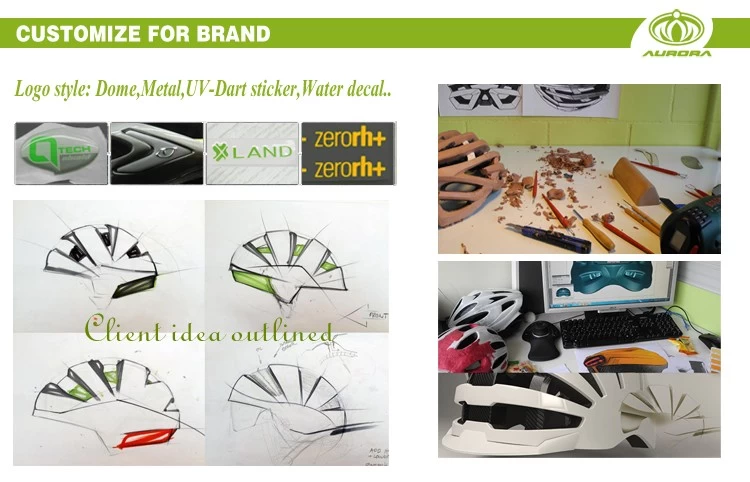

Design & Creativity

Our in-house design facility coupled with our creative Account team enables us to create innovative helmets ideally suited to our clients target market - the company combines creativity and sourcing in a unique partnership to bring the best to any sports campaign.

The helmet production procedure is as below:

silk screen → PC blister tooling → PC blister manufacture → Trimming dug hole → EPS raw material by different density → EPS in-mold tooling → helmet in-mold workshop → in-mold machines → in-mold tooling → in-mold producing process → semi-finished in-mold helmet → IQC inspection → helmet grinding → inner padding production → plastic injection workshop → assembly line →inside labeling → packing → warehouse → installed counters.