Innovative design in-house

As soon as you are planning to design a helmet, our design team will assist you throughout the process. Each team member R & D has a long and strong experience in drawings and can come up with ideas that cover all styles of helmets. Early on, you can find trendy tables from which you can get inspiration for creating the model. Our design team will then take you lead, who accompany you through all the steps.

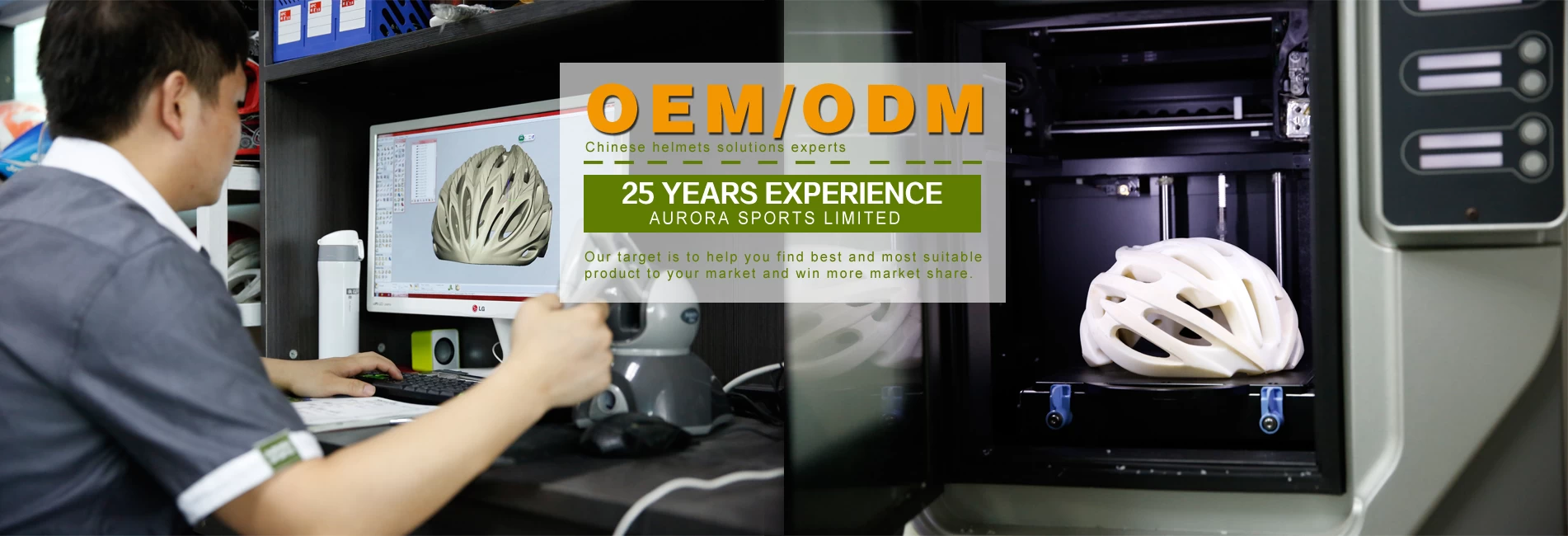

Rapid prototyping

Aurora sports sets production sketches, an experienced team of professional helmet totally dedicated to customer satisfaction. Focusing on innovation, creativity and production, Aurora sports uses CNC Prototyping 3D printing equipment and machinery, if necessary. This will enable our product development team create a helmet and some accessory helmet in volume before going to any type of tooling. Exploiting this know-how, our design team has the opportunity to correct any details at low cost and produce 3D prototypes within 15 days.

Production of the helmet

Aurora sports is a manufacturer of helmet, with more than 25 years of experience in the production of helmets.

In-house design and R & D teams with experience, allows Aurora to respond quickly to the most demanding

requirements and create from scratch entire programs and collections with rigorous quality standards.

-

1 printing and screen printing

We use non-toxic, eco-friendly paint for our entire press. We have the machines and the ability to do the following: Mitsubishi 4-color offset printing, silk screen printing, stamping machines, soft UV printing, UV varnishing, offset printing, sublimation, decorative decal, water transfer printing and many more.

-

2 PCS blister tooling and blister production

We completely relevant equipment, tooling, all materials are eco-friendly and non-toxic.

-

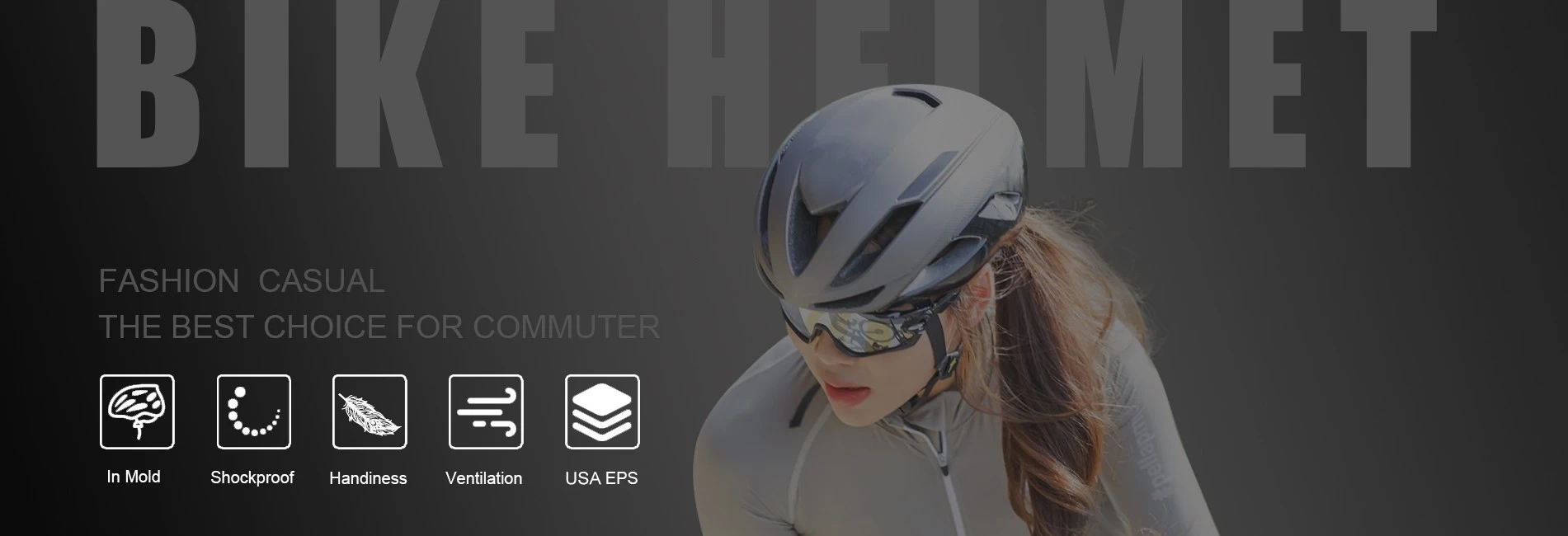

in-mould workshop 3

In-mold helmet is the process in which the PC (poly carbonate thin outer shell) is adhered directly (with heat and glue) to the EPS liner. This process is used to make bicycle helmets. It is also becoming widely accepted in other industries to make lightweight helmets but strong for many other applications such as parachuting, paragliding, ice skating, etc. Our EPS material is imported from countries such as USA, Germany and Austria. High density EPS, it means that you can easily move all your certifications required without any worries. All materials are NON-toxic, standard 7 p.

-

4 plastic injection molding machine

All plastic and rubber or is homemade. This gives us the ability to maintain high quality standards, no delays in production schedules and the biggest advantage is, you can save more money.

-

5 inside comfort heat producing pads

-

Carbon fiber helmet 6 modeled after vacuum forming

-

7 assembly line and QC/QA department.

Our quality system is composed of:1) IQC (quality control)2) IPQC (In-Process quality control)3) Quality Assurance (QA)Our QA/QC Department performs strict quality control measureson all incoming materials and accessories,Them to follow and check quality seriously through the entire process,material control before production, production control, monitoring the packing and doing final inspection beofore delivery, etc.

-

8 warehouse and shipping

Our normal package is: PP bag + color box + carton