American National Standard for Industrial Head Protection - helmet manufacture

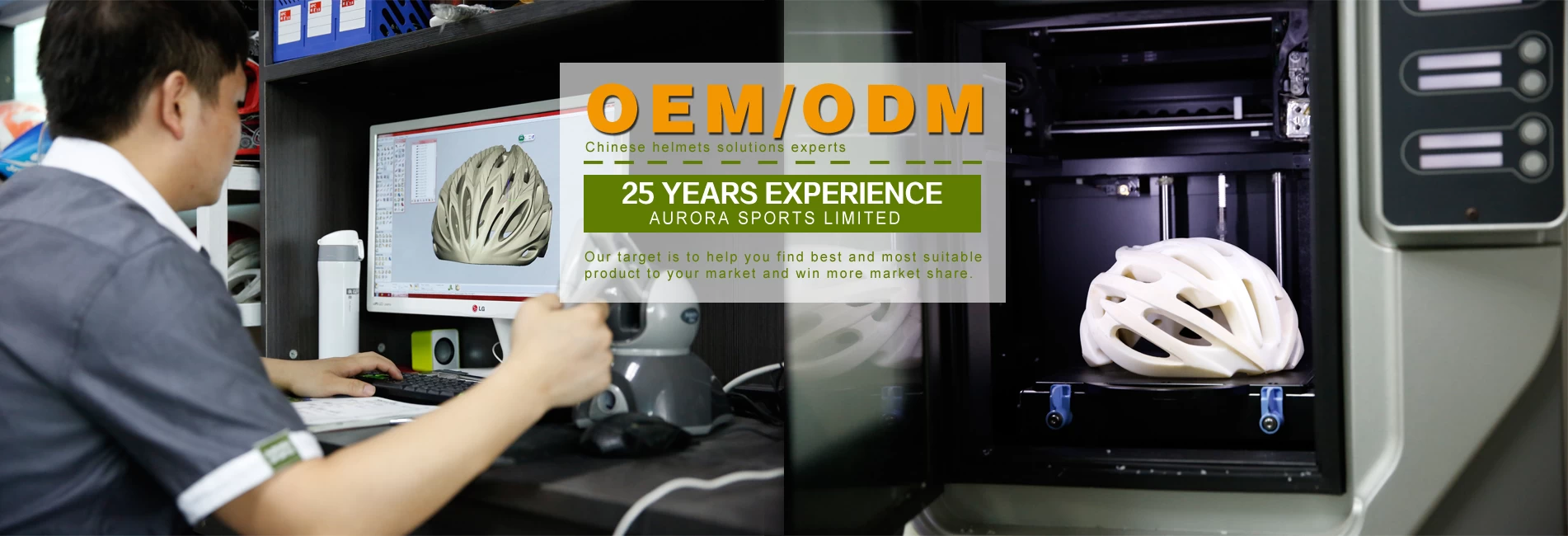

aurora

helmet

2017-06-22 11:20:47

On May 15, 2014, American National Standards Institute (ANSI) issued approval for ANSI/ISEA Z89.1-2014, American National Standard for Industrial Head Protection.

What is ANSI/ISEA Z89.1-2014?

ANSI/ISEA Z89.1-2014 Standard (the “Standard”) provides industrial hard hat performance and testing requirements. The Standard establishes types and classes of protective helmets to provide employers with hard

hat options that provide appropriate protection for hazards present in a given workplace. The Standard addresses the following:

• Specifications for helmets by Type (based upon impact force location) and Class (based upon electrical insulation);

• Impact occupational settings under normal temperature conditions and, optionally, pre-conditioning to higher and lower temperatures;

• Safety recommendations for hard hats worn in the reversed position;

• Requirements for high-visibility helmets;

• Test methods for evaluating all requirements; and

• User cautions and recommendations regarding helmet care.

Why was a new Standard created?

Voluntary industry consensus standards recognized by ANSI are required to be reviewed every five years; the previous edition was ANSI/ISEA Z89.1-2009.

What updates have been made to ANSI/ISEA Z89.1-2014?

Core performance requirements remain unchanged; however, three important updates to ANSI/ISEA Z89.1-2014 are listed here:

The new Standard and Product Compliance

ANSI/ISEA Z89.1-2014 does not require users to discontinue using products labeled as compliant with the 2009 Standard. However, if your occupation requires compliance with new optional certifications such as pre-conditioning at higher temperature, older product will not be marked and may not be compliant. When in doubt, check with AURORA for specific requirements.

Conclusion

Worker safety is always the highest job site priority, and head protection is an essential element in providing workers with protection from falling debris, low hanging objects and electrical hazards. A Standard-compliant, properly marked hard hat should be worn in all situations where head protection hazards exist.

If you want to buy high quality helmets, welcome to consult the Chinese helmet manufacturer: + 86-755-23048882

What is ANSI/ISEA Z89.1-2014?

ANSI/ISEA Z89.1-2014 Standard (the “Standard”) provides industrial hard hat performance and testing requirements. The Standard establishes types and classes of protective helmets to provide employers with hard

hat options that provide appropriate protection for hazards present in a given workplace. The Standard addresses the following:

• Specifications for helmets by Type (based upon impact force location) and Class (based upon electrical insulation);

• Impact occupational settings under normal temperature conditions and, optionally, pre-conditioning to higher and lower temperatures;

• Safety recommendations for hard hats worn in the reversed position;

• Requirements for high-visibility helmets;

• Test methods for evaluating all requirements; and

• User cautions and recommendations regarding helmet care.

Why was a new Standard created?

Voluntary industry consensus standards recognized by ANSI are required to be reviewed every five years; the previous edition was ANSI/ISEA Z89.1-2009.

What updates have been made to ANSI/ISEA Z89.1-2014?

Core performance requirements remain unchanged; however, three important updates to ANSI/ISEA Z89.1-2014 are listed here:

①Section 7.3.3 Higher Temperatures

The revision enables additional protection in response to the needs of users who may work within hot environments. 2009 Standard hot temperature conditioning was 48.8°C ± 2°C (120°F ± 3.6°F). Optional preconditioning at higher temperatures of 60°C ± 2°C (140°F ± 3.6°F) has been added to the 2014 version. If a helmet has been preconditioned to 60°C ± 2°C (140°F ± 3.6°F), the helmet will be marked as HT. In addition, new updates allow for flexibility and inclusion of emerging and current best manufacturing materials for higher temperature protection.

Caveat: the Standard does not address pre-conditioning that could be needed for temperature and radiant heat extremes. To ensure that you have the proper head protection level needed for your specific heat application, check with the manufacturer for stated usage of any helmet

The revision enables additional protection in response to the needs of users who may work within hot environments. 2009 Standard hot temperature conditioning was 48.8°C ± 2°C (120°F ± 3.6°F). Optional preconditioning at higher temperatures of 60°C ± 2°C (140°F ± 3.6°F) has been added to the 2014 version. If a helmet has been preconditioned to 60°C ± 2°C (140°F ± 3.6°F), the helmet will be marked as HT. In addition, new updates allow for flexibility and inclusion of emerging and current best manufacturing materials for higher temperature protection.

Caveat: the Standard does not address pre-conditioning that could be needed for temperature and radiant heat extremes. To ensure that you have the proper head protection level needed for your specific heat application, check with the manufacturer for stated usage of any helmet

②Section 5: Accessories and Replacement Components

While already a Z87 face protection requirement, the Standard 2009 version indicated that accessories or components installed onto hard hats cannot cause the helmet to fail. The 2014 Standard update provides additional language further supporting the premise that accessory/component manufacturers are responsible for proving that their products do not cause helmets to fail: “The entity claiming that an accessory or replacement component, when installed, will not cause the helmet to fail the requirements of this Standard, and is responsible for providing justification upon request.”

③Section 6: Instructions and Markings

Clarification language was added to this section to help customers understand that “useful service life” for helmets is not required by the Standard, although helmet manufacturers may choose to include it. “NOTE: Useful service life guidelines are intended to provide the user with information that certain conditions may affect a specific helmet’s continued protection over time. A specific service life, defined in terms of number of years, is not required though individual manufacturers may choose to include such information for their respective helmets.”

Clarification language was added to this section to help customers understand that “useful service life” for helmets is not required by the Standard, although helmet manufacturers may choose to include it. “NOTE: Useful service life guidelines are intended to provide the user with information that certain conditions may affect a specific helmet’s continued protection over time. A specific service life, defined in terms of number of years, is not required though individual manufacturers may choose to include such information for their respective helmets.”

The new Standard and Product Compliance

ANSI/ISEA Z89.1-2014 does not require users to discontinue using products labeled as compliant with the 2009 Standard. However, if your occupation requires compliance with new optional certifications such as pre-conditioning at higher temperature, older product will not be marked and may not be compliant. When in doubt, check with AURORA for specific requirements.

Conclusion

Worker safety is always the highest job site priority, and head protection is an essential element in providing workers with protection from falling debris, low hanging objects and electrical hazards. A Standard-compliant, properly marked hard hat should be worn in all situations where head protection hazards exist.

If you want to buy high quality helmets, welcome to consult the Chinese helmet manufacturer: + 86-755-23048882